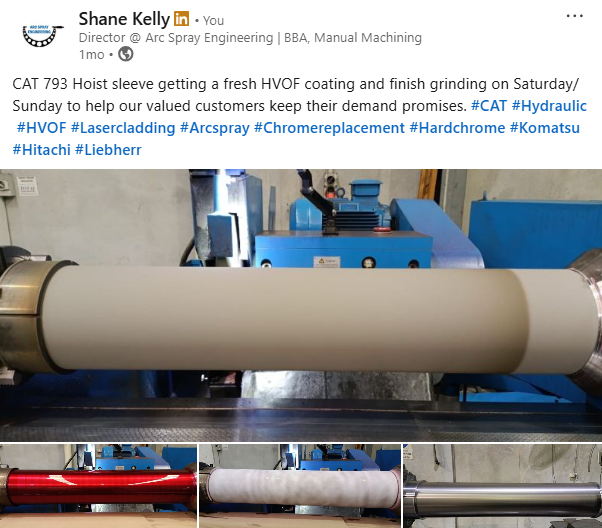

🚀 High Velocity Oxy-Fuel (HVOF) Coating

Dense, hard, and highly wear-resistant thermal spray coatings

High Velocity Oxy-Fuel (HVOF) is a thermal spray process that creates an ultra-high velocity jet by combusting fuel and oxygen. Coating powders are injected into this supersonic stream, partially melted, and propelled onto the substrate at speeds exceeding Mach 1. The result is a dense, low-porosity coating with exceptional hardness and adhesion.

HVOF is widely used to protect critical components against abrasion, erosion, and corrosion in the harshest environments.

✅ Key Advantages of HVOF

-

Dense, Low-Porosity Coatings – Supersonic particle velocity ensures high packing efficiency and minimal porosity.

-

High Hardness & Strength – Low carbide decomposition and excellent interlamellar cohesion deliver superior wear resistance.

-

Crack Resistance – Microstructures with mixed columnar and equiaxed grains reduce crack propagation.

-

Controlled Oxidation – Relatively cooler particle temperatures reduce oxidation and preserve material integrity.

-

Versatility – Metals, hard ceramics, carbides, and specialty alloys can all be applied with HVOF.

📌 Applications

HVOF coatings are ideal for components exposed to extreme wear, erosion, and corrosion, such as:

-

Mining equipment requiring maximum wear resistance

-

Mineral processing components in erosive-corrosive duty

-

Engines, transmissions, and driveline parts

-

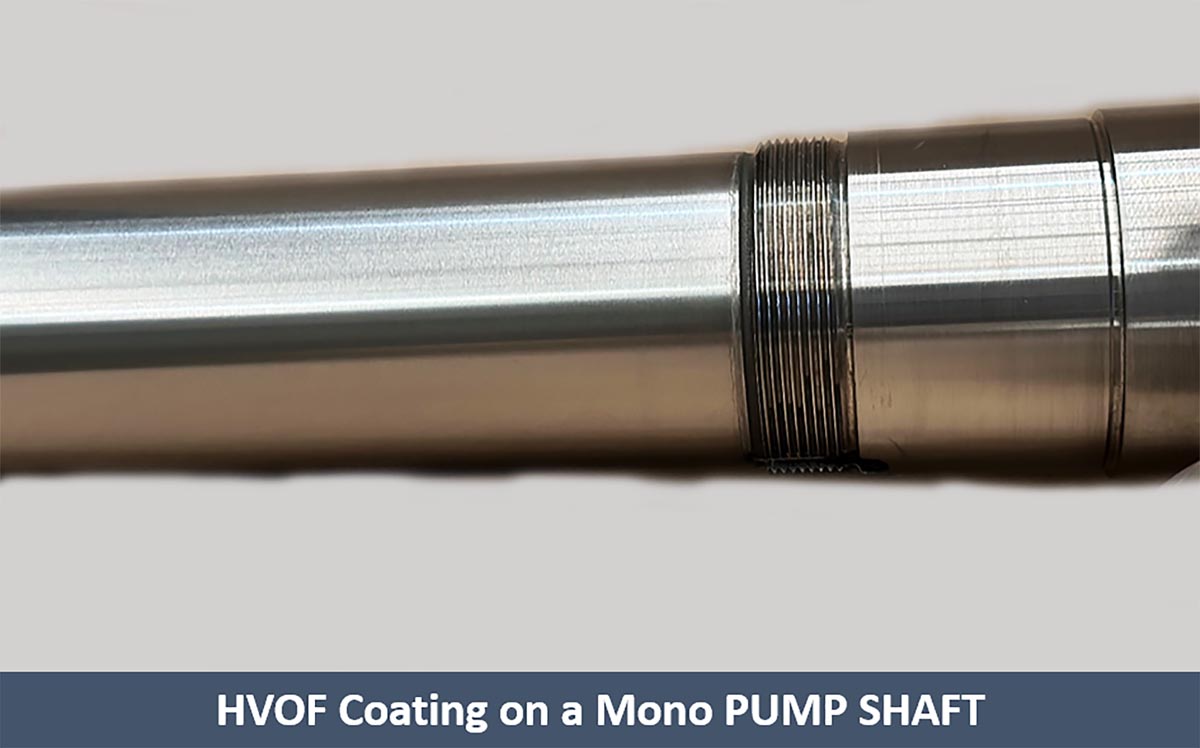

Oil & Gas pumps, valves, and bearing housings

-

Braking systems

-

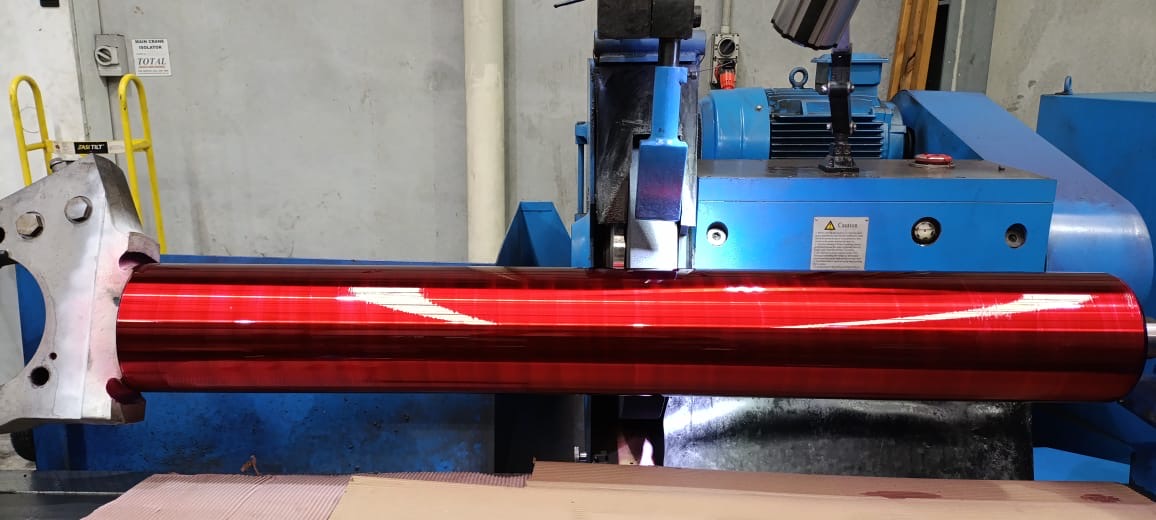

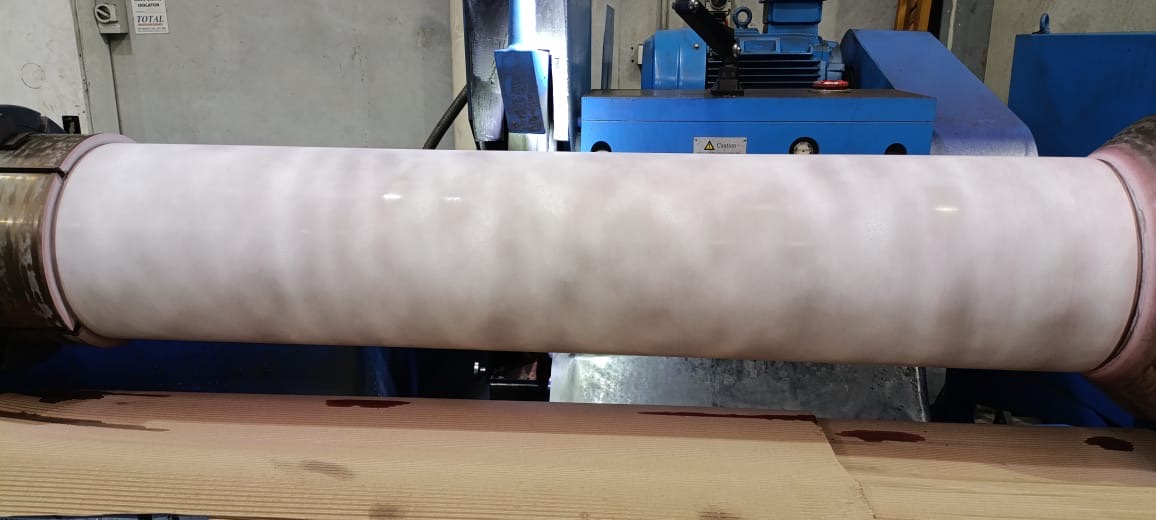

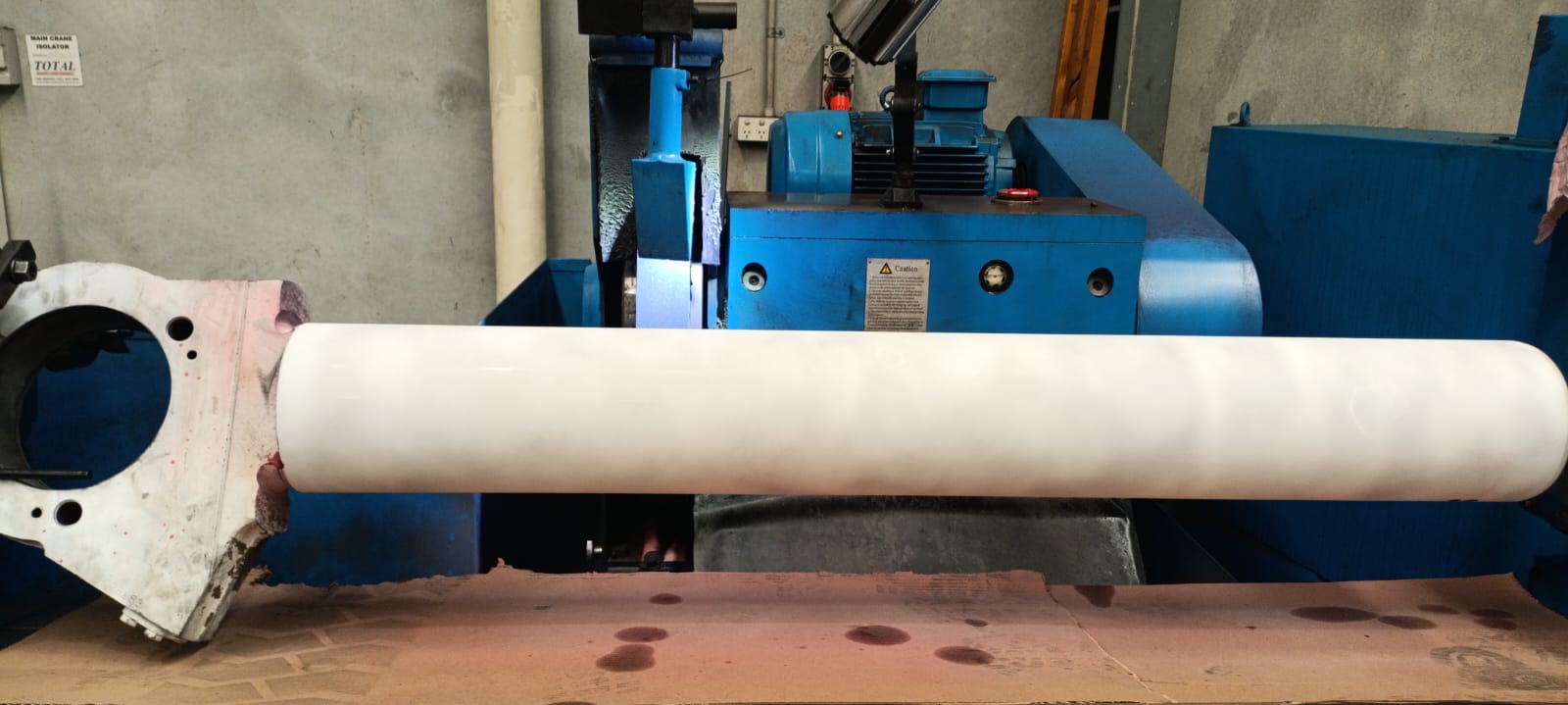

Hydraulics and high-pressure equipment

🛠️ Our HVOF Capabilities

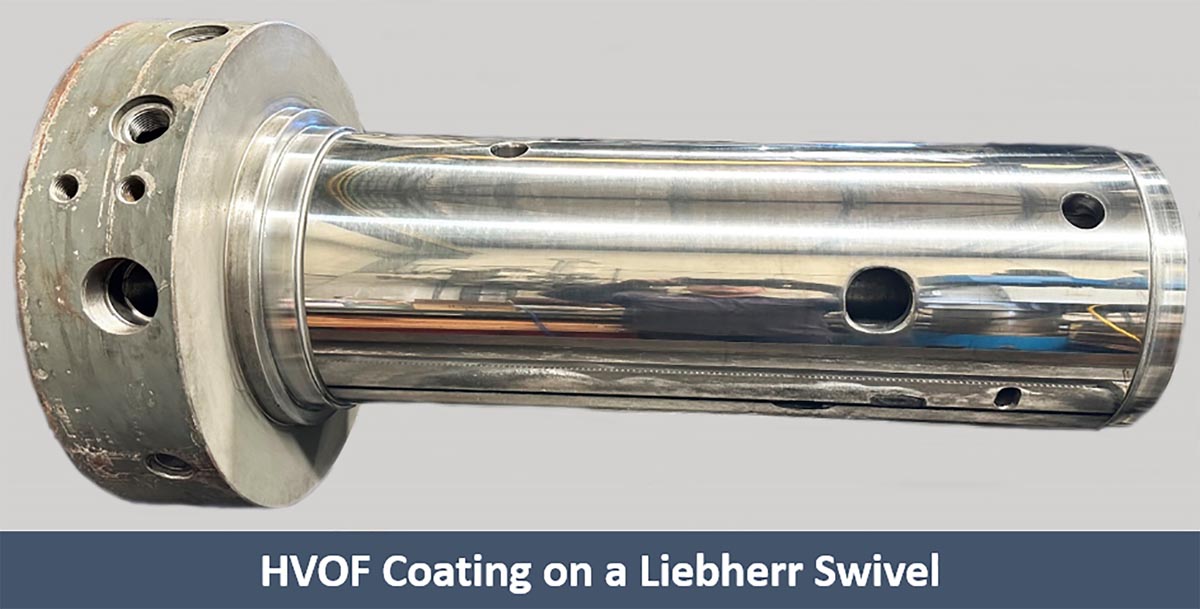

At Arc Spray Engineering, we apply HVOF coatings of hard ceramics and advanced alloys onto metallic substrates. By carefully selecting coating materials and optimizing process parameters, we deliver solutions that:

-

Restore worn components to service

-

Maximize wear and corrosion resistance

-

Extend service intervals in extreme operating environments

📞 Protect Your Critical Equipment

Arc Spray Engineering’s HVOF coating facility helps you reduce downtime and extend the life of essential components.

📞 Contact us today to discuss how our HVOF coatings can boost the performance and reliability of your equipment.