Arc Spray Engineering provides innovative solutions for restoring your high value components and equipment with improved performance. Please see the range of services we offer to achieve a new life for your components and equipment through our sustainability and circular economy approaches.

OUR SERVICES

Dimensional Restoration

Experts

SUSTAINABILITY

The Green &

Sustainable choice in

mining

According to the World Steel Association, producing one ton of steel emits an average of 1.85 tons of CO2 — roughly 8% of global CO2 emissions. Reducing the need for new steel through repair and reconditioning is therefore a simple, high‑impact way to cut emissions and operating costs.

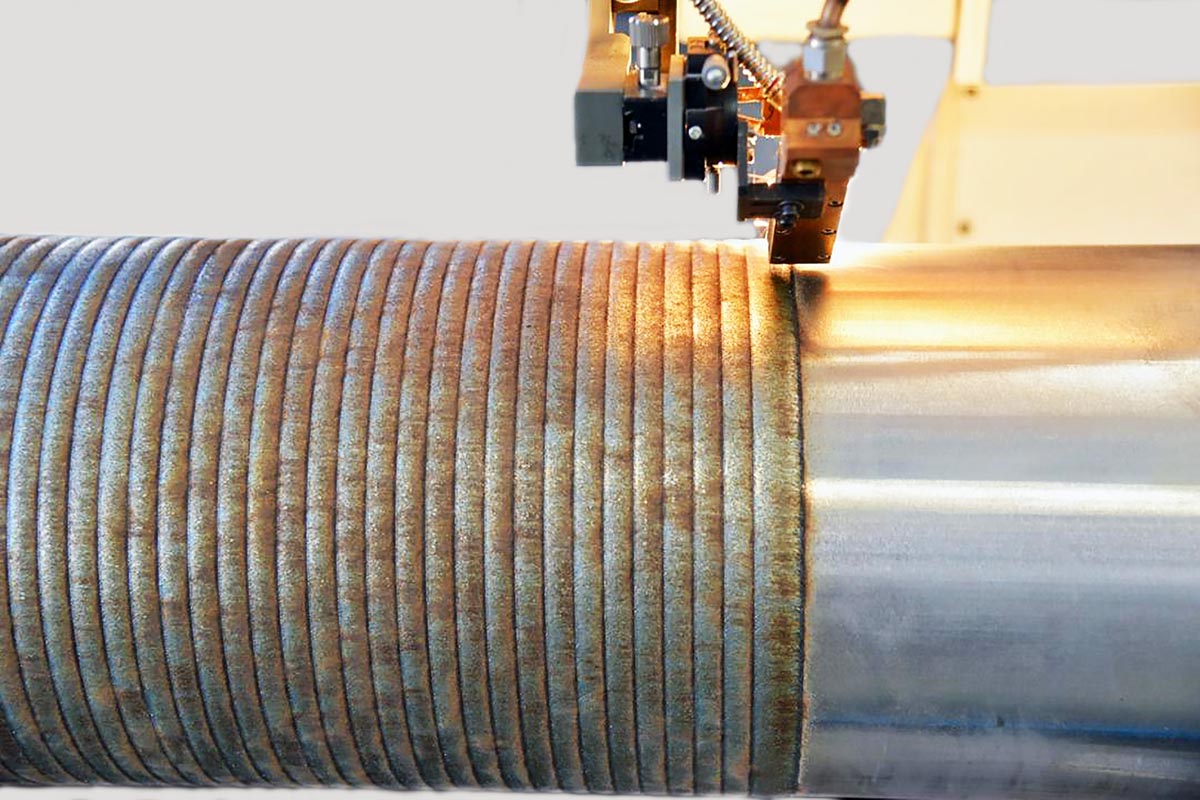

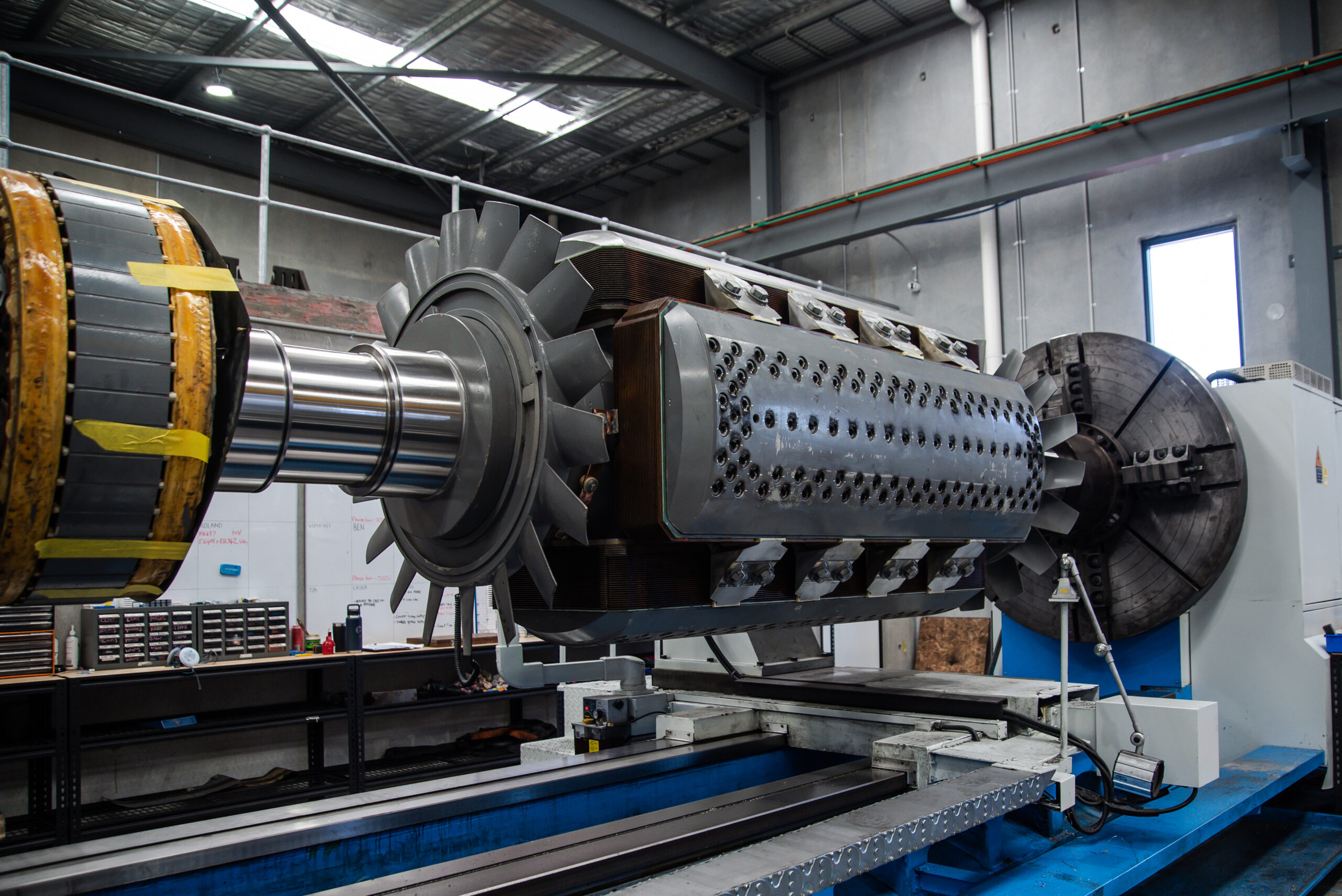

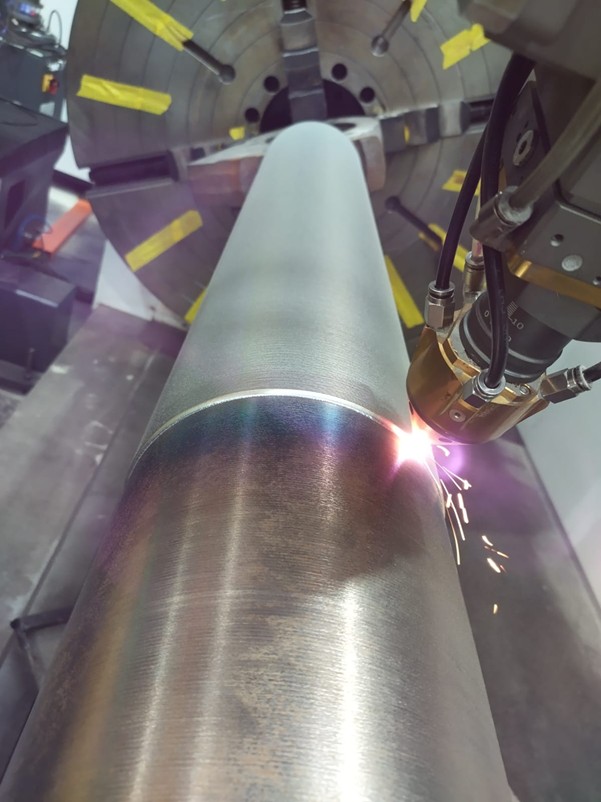

Surface modification and repair are now recognized as environmentally friendly solutions for rebuilding and improving component performance. At Arc Spray Engineering we use a range of proven processes — Arc spray, HVOF (High Velocity Oxygen Fuel), APS (Atmospheric Plasma Spray) and Laser cladding — to restore components to original dimensions or upgrade them beyond OEM performance. By matching the right process and materials to each application, we produce durable, wear‑resistant surfaces that extend service life and reduce whole‑of‑life costs.

Why repair with surface modification matters

- Lower emissions and material waste — repairing parts avoids new steel production and the associated CO2 footprint.

- Faster return to service — new components can be delayed in transit (sometimes up to 120 days); our typical repair turnaround is 1–3 weeks.

- Cost efficiency — repairs are often a fraction of the replacement cost while delivering equal or better performance.

- Improved asset performance — tailored coatings and laser cladding can deliver superior hardness, corrosion resistance and dimensional accuracy.

Our capability

- Arc spray: cost‑effective dimensional restoration for Wheel Hubs & Trunnions etc.

- HVOF: dense, high‑bond coatings for Hydraulic rod Chrome replacement.

- APS (Atmospheric Plasma Spray): versatile ceramic coatings for thermal and wear resistance on Pump sleeves and boiler components.

- Laser cladding: precision remanufacture and metallurgical bonding for worn geometry on Crusher Components, Gearbox shafts / Bores and Chrome replacement for Hydraulic rods.

We repair hundreds of tons of machinery components each year and believe many more parts can be saved from scrap with the right specification and process selection. If your organization is targeting both environmental and economic performance improvements, contact Arc Spray Engineering — with our materials selection, machining, welding and surface‑modification capabilities, we’ll restore your components quickly and reliably.

Call us or request a repair quote to discuss how we can reduce your downtime, lower costs and support your sustainability goals.

NEWS

Industry Insights

& Innovations

We have wide range of coating facilities at Arc Spray Engineering which includes Arc Spray, HVOF, APS and Laser Cladding. The coating process can be chosen based on the application, service environment and materials.

FAQS

Frequently Asked

Questions

We are located at Forrestdale, a master planned industrial area which is 30 minutes from Perth CBD.

Address:

8B Weedon Road,

Forrestdale WA 6112

Please use any of the following contacts to reach us. We will make sure to get back to you within 24 hours after receiving any request from you.

Phone: (08) 9398 3500 (International: +61 8 9398 3500)

Email: admin@arcsprayengineering.com.au

Arc Spray Engineering provides turnkey solutions for restoring mining and mineral processing components since 2011. We have many in-house repair techniques and will choose the most suitable method to restore your components and equipment to their original condition. We are committed to quality, timeline and R&D which will continue to provide excellent value for money to our clients.

We repair hundreds of tons of machinery components annually but we know there is a lot more going to scrap that could be saved using surface modification processes so we are trying to get the message out that, many machinery components can be repaired for a fraction of the replacement price using our sustainable surface modification process.

Yes, we provide our service to all around Australia. Our customers are based all over Australia from one-off private customers, country workshops, to large mining, Oil & Gas and engineering companies.

Our continual improvement programs and R&D lab ensure we are on the leading edge in our field and will continue to be recognized as the most professional operators in Australia – Please see our range of services and send any inquiries as we welcome new challenges. We provide quality, prompt and competitively priced services.

We are well experienced and equipped with weld repair and coating of cast iron components without any defects. We provide quality service to your cast iron components in a shorter time span to get your regular operations up and running with minimal downtime

Aluminium has combination of strength, light weight, versatility and corrosion resistance which makes it a cost effective choice of material for any industry. However, Aluminium has poor wear resistance which restricts its use in high pressure and stress environments. We are experienced in providing great surface coatings with different materials to improve the performance of the Aluminium components. Please contact us to restore your aluminium components with improved properties.

We are highly experienced and qualified in providing improved wear resistance on any of the components. We carefully choose the materials and processes from our experience to restore your components to their original conditions with improved performance.

We work closely with many mineral processing, chemical and oil & gas industries to provide solutions for restoring the components used in severe corrosive environments. We are highly experienced in selection of coating materials and processes for the components used in strong acids (oxidising and reducing), base and sea water. Hence, we are confident that we will restore your components with improved performance in the highly corrosive medium.

Erosion-Corrosion is an accelerated attack of metal surface by the flow of corrosive fluid and hard particles with high pressure. Erosion-Corrosion on any of the components can be minimised by having combination improved wear and corrosion resistant coating materials. Although, the task is challenging, our continual improvement programs and R&D made a pathway to develop coating materials for improving Erosion-Corrosion resistance of the components. Please contact us to improve your components performance in erosive-corrosive environments.